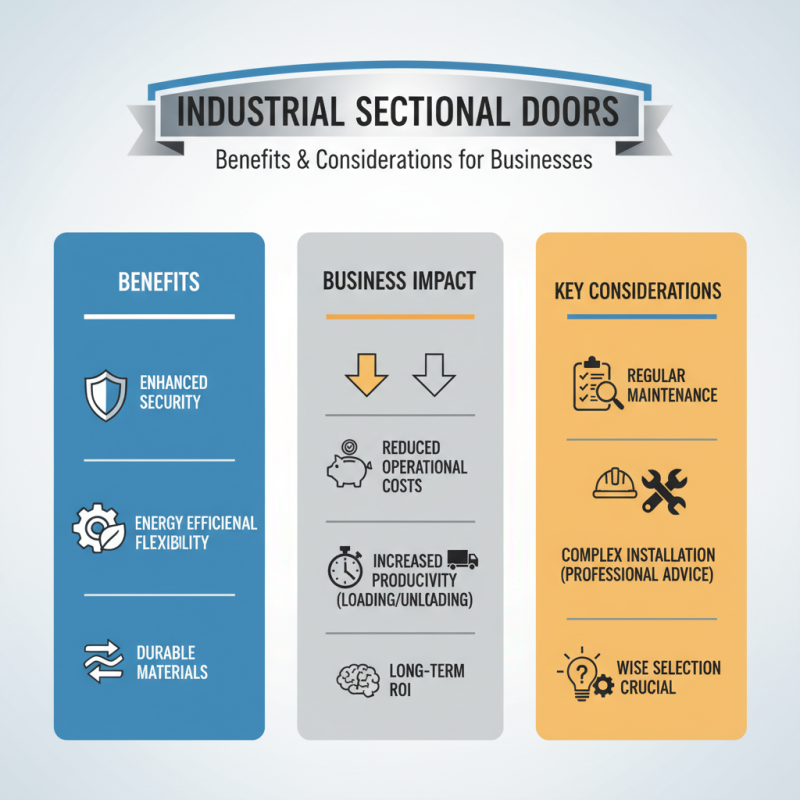

You know, industrial sectional doors are really starting to take off across different industries. They’re not just fancy features—they actually bring some pretty solid benefits for businesses. I was chatting with John Thompson from Industrial Door Solutions the other day, and he summed it up perfectly: “Industrial sectional doors bring security, efficiency, and flexibility to the table.”

These doors are usually built from tough materials that can handle rough conditions without breaking a sweat. Not only do they bump up safety, but they also help keep energy bills in check—cutting down operation costs in the long run. But, uh, I’d say one thing folks should keep in mind is that these doors do need regular upkeep. Checking on them now and then is super important to keep everything running smoothly.

Most businesses find that, even after the initial investment, they start seeing the benefits pretty quickly. Loading and unloading gets way more efficient, which means higher productivity overall. Of course, there’s usually a bit of a learning curve when it comes to installing these doors—that’s why it’s always worth getting professional advice. When chosen wisely, these doors can really streamline how your operations work and make a big difference.

Overview of Industrial Sectional Doors

Industrial Sectional Doors are widely used in warehouses and manufacturing facilities. They consist of several horizontal sections that move vertically. This design allows them to open and close efficiently, saving space. Many businesses find this beneficial for both operations and safety.

These doors can be built with various materials, enhancing durability. Steel, for example, offers strength against heavy use. However, the choice of material can impact costs. Not all options are equally easy to maintain. Regular inspections are essential, or they may face unexpected repairs down the line.

Another aspect to consider is insulation. Some sectional doors come with insulation, helping regulate temperature. This feature can reduce energy costs, but it may increase the initial expense. Businesses must balance these factors to find the right fit. Proper planning and decision-making are key to maximizing benefits.

Key Features of Industrial Sectional Doors

Industrial sectional doors are a popular choice in various sectors. Their design allows for efficient use of space. These doors open upwards, saving ground area. This feature is crucial for warehouses and factories where space is limited.

One key feature is the insulation capability. Many industrial sectional doors come with energy-efficient panels. This helps maintain a stable indoor temperature. It reduces heating and cooling costs. Additionally, they are designed for durability. Made with robust materials, they withstand heavy use. This longevity can lead to cost savings over time.

However, installation can be complex. It's vital to ensure proper fitting and alignment. Inadequate installation may lead to performance issues. Regular maintenance is necessary to avoid unexpected repairs. These aspects require careful planning and execution.

Advantages of Using Industrial Sectional Doors

Industrial sectional doors offer numerous advantages for warehouses and manufacturing facilities. These doors are designed for high efficiency and durability. According to a report by the American Architectural Manufacturers Association, sectional doors can improve operational workflow by 35%. This efficiency is crucial for busy environments where time is money.

One notable benefit is the enhanced insulation properties. A study from the International Door Association indicates that insulated sectional doors can reduce energy costs by up to 20%. This is particularly vital in climate-controlled settings. Proper insulation keeps temperatures stable, lowering heating or cooling demands. However, there may be initial costs associated with high-quality insulated doors, which requires careful budgeting.

Another advantage lies in safety features. Many sectional doors come equipped with advanced safety mechanisms. Reports highlight that injuries related to malfunctioning doors have decreased by 25% due to modern innovations. However, some facilities still face challenges in maintenance. Regular checks are necessary to avoid potential hazards. Skipping maintenance can lead to costly repairs or accidents. Hence, while industrial sectional doors have distinct benefits, ongoing vigilance is essential.

Energy Efficiency Benefits of Sectional Doors

Industrial sectional doors offer significant energy efficiency benefits. They create a tight seal, minimizing air leaks. This is crucial in industrial settings where temperature control is vital. Research indicates that installing sectional doors can reduce energy costs by up to 30%. The right door can help maintain a stable environment, reducing heating and cooling needs.

In addition, sectional doors often use insulation materials that enhance their energy performance. According to industry reports, insulated sectional doors can provide an R-value of 18 or higher. This means better resistance to heat transfer, resulting in easier climate control. Many facilities report less strain on HVAC systems when using these doors. This can extend the life of equipment, but not all models achieve the same results.

Despite these advantages, some facilities still struggle with door performance. Poor installation or inadequate maintenance can negate these benefits. Regular inspections are needed to keep the doors functioning properly. Businesses should consider these factors to fully utilize the energy-saving potential of sectional doors.

Enhanced Security Provided by Industrial Sectional Doors

Industrial sectional doors provide enhanced security that many businesses require today. These doors are designed with robust materials, ensuring they withstand various threats. With thicker panels and reinforced frames, they deter unauthorized access effectively. This added strength is essential in high-value environments, where protection is a priority.

When choosing industrial sectional doors, consider the locking mechanisms. High-quality locks make it harder for intruders to break in. Regular maintenance is crucial, as worn-out locks compromise security. Inspect doors frequently to ensure they function optimally.

Another tip involves automation. An automated door system can prevent unauthorized access more effectively than manual systems. Incorporating keycard entry or security codes adds an extra layer of safety. However, ensure staff are trained in these systems. If employees forget access codes, it could lead to delays and security breaches. Prioritize training to maintain smooth operations.

Enhanced Security Provided by Industrial Sectional Doors

This chart illustrates the various benefits of industrial sectional doors that enhance security, including intrusion deterrence, damage resistance, access control, fire resistance, and energy efficiency. The percentages represent their effectiveness in improving security measures.

Maintenance and Durability of Sectional Doors

When it comes to sectional doors, maintenance is key. Regular inspections can prevent bigger issues down the line. Check the tracks for dirt and debris. A clean surface helps the door slide better. Make sure the springs are adjusted properly. Untensioned springs can wear out quickly. Lubricating the moving parts is also essential. This small step can make a huge difference in functionality.

Durability is another focus for sectional doors. They are designed to withstand tough conditions. High-quality materials resist wear and tear. However, even durable doors can face challenges. Weather changes can affect performance. Extreme temperatures may cause warping or cracking. It’s important to monitor the door's condition over time. Fading paint or rust spots may signal the need for repair. Addressing these issues promptly will extend the lifespan of the door.

In conclusion, regular maintenance ensures the durability of sectional doors. By keeping an eye on their condition, you can avoid costly repairs. However, it's easy to overlook these tasks in a busy environment. Creating a maintenance schedule could help. Don’t let your door's health fall by the wayside.

Applications of Industrial Sectional Doors in Various Industries

Industrial sectional doors play a crucial role in various sectors. They are common in logistics centers and warehouses. These doors help to improve energy efficiency. A report indicates that proper door systems can reduce heating and cooling costs by up to 30%. This means businesses can save significant sums annually.

In manufacturing, sectional doors enhance workflow. They allow quick access for trucks and employees. Quick lifting speeds minimize downtime. In fact, data shows that facilities with efficient door systems see a 15% increase in productivity. However, industries sometimes overlook maintenance. This can lead to operational issues. Regular checks are essential to avoid costly repairs.

In cold storage facilities, sectional doors play a vital role. They help maintain temperature control. Research shows that improper sealing can lead to temperature deviations of up to 10 degrees. Maintaining consistent temperatures ensures product quality. Yet, many operators fail to monitor door seals adequately. This oversight can compromise their goods. Understanding these applications highlights the importance of sectional doors in diverse settings.

Enhancing Energy Efficiency: The Role of Hinge Insulated Doors and Hinge Clean Doors in Commercial Building Performance

In the quest to enhance energy efficiency within commercial buildings, the implementation of hinge insulated doors and hinge clean doors plays a pivotal role. These advanced door solutions are particularly beneficial in environments that demand strict temperature control, such as cold chain logistics, food processing, and health care facilities. With door leaf thickness varying from 50mm to 200mm, these doors provide robust insulation that minimizes heat transfer, thus reducing energy costs significantly. Industry reports suggest that improved door insulation can lead to a 50% reduction in energy consumption for temperature-sensitive operations, underscoring the economic and environmental advantages of using such products.

Hinge insulated doors are designed to operate effectively within a temperature range of -80℃ to +200℃, making them versatile for various applications, including ice cream factories and high and low temperature laboratories. The innovative designs, which allow for single or double door leaf configurations as well as floating openings and sink closures, ensure enhanced functionality and ease of use. With a designed lifespan of about 15 years, these doors not only contribute to operational efficiency but also promise long-term investment value for commercial establishments. The ability to maintain stringent hygiene standards without compromising on thermal performance further solidifies their importance in the food and medical sectors.

Moreover, the global power adaptability of these doors ensures their compatibility with diverse operational settings, enhancing their appeal across international markets. As buildings increasingly aim to meet energy efficiency benchmarks, the strategic selection of door solutions becomes essential. By opting for hinge insulated and hinge clean doors, commercial entities can align themselves with both sustainability goals and the expectations of modern consumers, reinforcing their commitment to responsible energy use and operational excellence.

FAQS

: The content aims to inform about various relevant topics.

Yes, the content provides practical tips for everyday situations.

No, the content is text-based without images or videos.

The content includes data and insights available until October 2023.

Yes, but ensure you adapt it to meet your specific needs.

Some topics might lack depth, requiring further research for clarity.

Reflect on how the advice applies to your situation personally.

Minimal emotional content is present, focusing more on practical advice.

It’s mostly straightforward, yet some sections may need careful reading.

Conclusion

Industrial sectional doors are specially designed for use in various industrial applications, offering a combination of functionality and security. These doors feature robust construction and insulation properties, making them suitable for high-traffic environments. The advantages of using industrial sectional doors include enhanced energy efficiency, as they help maintain climate control within facilities, and improved security, providing a strong barrier against unauthorized access.

In addition to their key features, these doors are known for their durability and low maintenance requirements, making them a cost-effective long-term solution. With a wide range of applications across different industries, industrial sectional doors play a crucial role in streamlining operations, ensuring safety, and enhancing overall productivity in warehouses, distribution centers, and manufacturing plants.