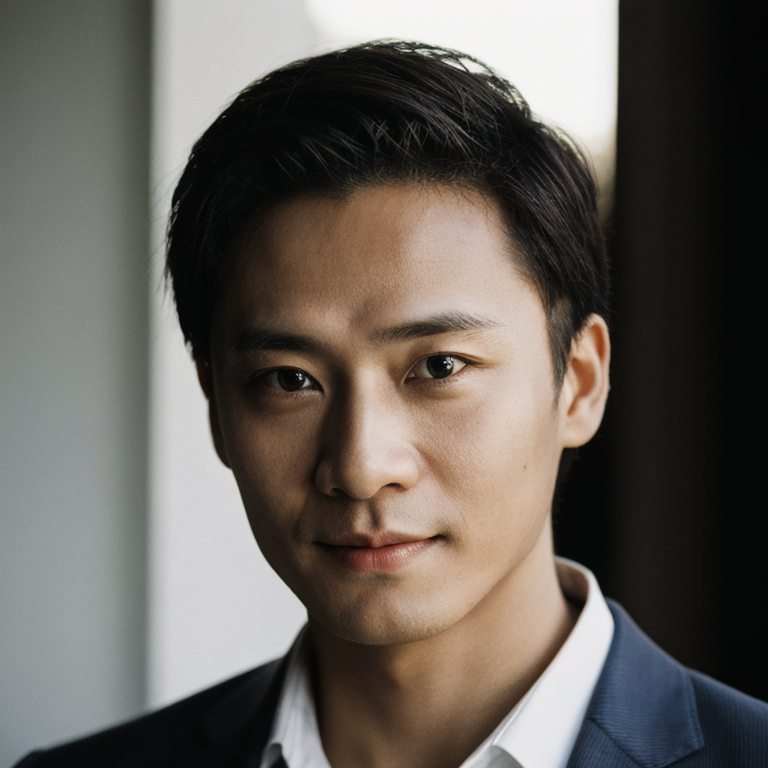

In the fast-paced world of logistics and warehousing, staying efficient is crucial if you want to keep a competitive edge. One thing that really makes a difference in smooth warehouse operations is the Dock Leveler. According to a report by the Material Handling Industry of America (MHIA), tweaking dock processes can cut loading and unloading times by up to 25%. That’s a huge deal, as it helps boost overall productivity. Essentially, a Dock Leveler acts as the essential bridge between the dock and the trucks or freight being moved in and out, making the whole process flow more smoothly and helping to prevent delays or accidents.

On top of that, OSHA stresses just how important it is to have reliable loading dock equipment. They point out that if your dock setups are sloppy or inadequate, it can lead to costly accidents and injuries—nobody wants that. Installing a Dock Leveler not only helps speed up cargo handling but also creates a safer workspace by reducing slips and falls. As the logistics world keeps changing and evolving, investing in good dock solutions like the Dock Leveler becomes pretty much a no-brainer for warehouses looking to stay efficient and safe. With consumer demands only getting higher, the benefits these Dock Levelers bring are really hard to ignore.

A dock leveler is an essential piece of equipment used in warehouses and distribution centers to bridge the gap between a loading dock and a truck or trailer. Essentially, it acts as a platform that adjusts to various heights, allowing for safer and more efficient loading and unloading of goods. By providing a smooth transition, dock levelers minimize the risk of slips, falls, and damage to both the cargo and the vehicles involved in the transporting process.

There are several different types of dock levelers, including hydraulic, mechanical, and air-powered options, each designed to meet specific operational needs. The primary function of a dock leveler is to enhance the flow of goods by ensuring that pallets and forklifts can move easily between the dock and the transport vehicle. This significantly reduces loading and unloading times, ultimately increasing the overall efficiency of warehouse operations. In a fast-paced environment where time is critical, the proper use of dock levelers can streamline logistics and improve productivity.

Dock levelers are essential components in modern warehouses, facilitating the seamless flow of goods between trucks and loading docks. There are several types of dock levelers, each designed for specific applications depending on the requirements of the warehouse environment.

The most common types include mechanical dock levelers, hydraulic dock levelers, and air-powereddock levelers. Mechanical dock levelers are cost-effective and require minimal maintenance, making them suitable for facilities with consistent loading conditions. On the other hand, Hydraulic Dock Levelers offer greater weight capacity and precise height adjustments, making them ideal for high-traffic areas or varying load sizes. Lastly, air-powered dock levelers utilize pneumatic systems to provide smooth transitions, ensuring quick loading and unloading processes while minimizing operator fatigue. Each type contributes to improved safety and efficiency in operations, allowing warehouses to maximize productivity with minimal downtime.

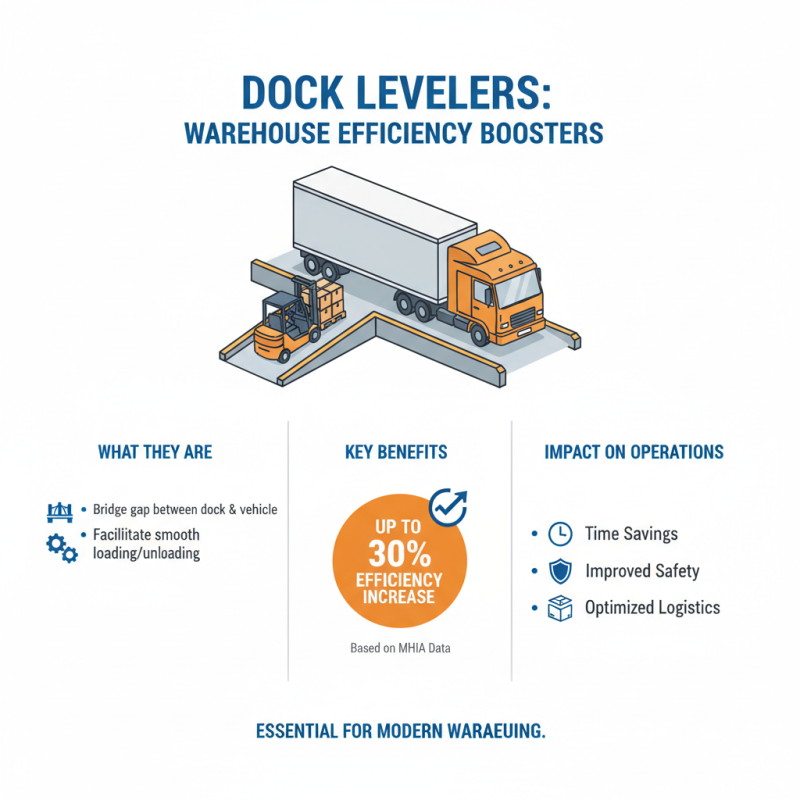

Dock levelers are essential components in modern warehouses, designed to bridge the gap between loading docks and delivery vehicles. These devices facilitate smooth and efficient loading and unloading processes, thereby significantly improving warehouse operations. According to data from the Material Handling Industry of America (MHIA), the right dock leveler can increase efficiency by up to 30%, showcasing their importance in logistics and warehousing.

Mechanically, dock levelers utilize various methods to adjust their height and bridge gaps. The most common types include hydraulic, mechanical, and air-powered levelers. Hydraulic dock levelers, for instance, employ hydraulic cylinders to raise and lower the platform, providing a seamless transition between the dock and the truck. This not only minimizes the risk of accidents but also speeds up the loading process. Research indicates that warehouses utilizing advanced dock leveler technology can reduce loading times by an average of 15-20%, leading to improved overall productivity.

Tips for enhancing dock leveler performance include regular maintenance checks to ensure hydraulic systems work efficiently and the platform remains free of obstructions. Additionally, investing in levelers with safety features such as Dock Seals and bumpers can significantly enhance safety during operation. Choosing the right leveler based on load capacity and frequency of use is also crucial for optimizing warehouse efficiency.

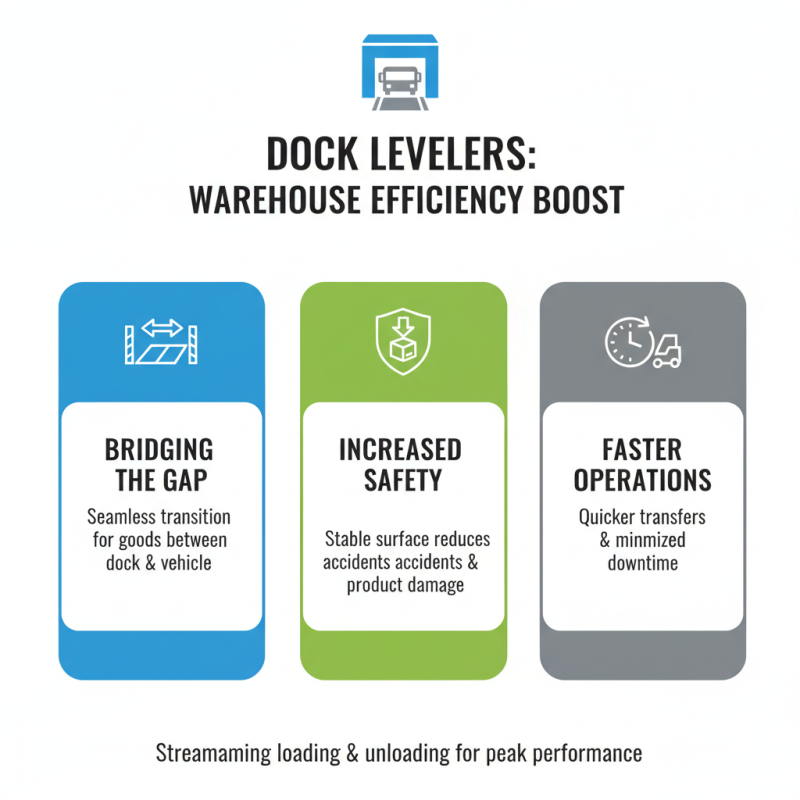

Dock levelers are essential tools that significantly enhance warehouse efficiency by bridging the gap between loading docks and trailers. Their primary function is to provide a smooth and safe transition for forklift trucks and goods during loading and unloading processes. By accommodating different heights of trucks, dock levelers minimize the need for manual adjustments and reduce the risk of accidents, leading to a more streamlined operation.

One of the key benefits of using dock levelers is the improvement in safety. With levelers in place, the likelihood of spills and falls decreases, ensuring a safer work environment for employees. Additionally, they help prevent damage to both the goods being handled and the vehicles involved. This improved safety translates to fewer accidents and a reduction in liabilities, ultimately saving time and resources.

Tips: Regular maintenance of dock levelers is crucial to maximize their lifespan and operational efficiency. Ensure that they are cleaned and inspected routinely for wear and tear. Also, consider training staff on proper usage to further mitigate risks and enhance productivity. Investing in high-quality levelers can lead to long-term gains in efficiency and safety within the warehouse.

Dock levelers play a crucial role in enhancing warehouse efficiency by streamlining the loading and unloading processes. These devices bridge the gap between the loading dock and vehicles, ensuring smooth transitions for goods. By providing a stable surface, dock levelers reduce the risk of accidents and product damage, which can frequently occur when loading and unloading from uneven surfaces. This stability not only protects inventory but also allows for quicker transfers, minimizing downtime during peak operation hours.

Moreover, the implementation of dock levelers can significantly optimize space utilization within a warehouse. With an efficient leveler in place, warehouses can manage multiple loading and unloading activities simultaneously without bottlenecks. This increases throughput and allows for better scheduling of shipments, improving overall operational flow. Additionally, by facilitating a more organized transfer process, dock levelers help maintain an effective inventory management system, ensuring that products are easily accessible and stored correctly, ultimately driving productivity and enhancing service delivery in a busy warehouse environment.

Maintaining dock levelers is crucial for ensuring the smooth operation of warehouse logistics. Regular maintenance not only enhances performance but also extends the lifespan of these essential systems. According to a report by the Material Handling Industry (MHI), properly maintained dock levelers can last significantly longer, yielding an estimated 30% lower replacement cost over time. Routine checks should include inspecting hydraulic systems for leaks, ensuring that electrical components are functioning correctly, and verifying that the leveling mechanisms are operating efficiently.

Additionally, keeping the dock area clean is vital. Accumulated debris can obstruct the dock leveler’s operation, leading to potential hazards and downtime. A study published in the Journal of Warehouse Management indicates that a clean working environment can reduce accidents by up to 25% and improve overall productivity. Implementing a regular cleaning schedule alongside mechanical inspections not only enhances safety but also minimizes wear and tear, thus contributing to the overall efficiency of warehouse operations. Regular lubrication of moving parts is also recommended to prevent rust and ensure smooth operation, further solidifying the importance of proactive maintenance strategies in logistics environments.

Future trends in dock leveler technology are paving the way for enhanced efficiency and safety in warehouse operations. As automation continues to revolutionize supply chain logistics, next-generation dock levelers are integrating smart sensors and IoT capabilities. These technologies allow for real-time monitoring of loading dock conditions, ensuring optimal performance and safety. For instance, sensors can detect the weight of incoming or outgoing goods, adjusting the leveler accordingly to minimize the risk of accidents and protect equipment from wear and tear.

Moreover, advancements in materials and design are leading to more durable and maintenance-free dock levelers. Innovations such as anti-corrosion coatings and reinforced structures are becoming standard, extending the lifespan of these systems and reducing downtime for repairs. Additionally, energy-efficient designs that reduce energy consumption during operation are gaining traction, responding to increasing demands for sustainability in warehouse management. With these technological advancements, dock levelers are not just improving operational efficiency; they are also playing a crucial role in creating safer and more sustainable work environments.

| Feature | Description | Efficiency Improvement | Future Trends |

|---|---|---|---|

| Hydraulic Operation | Uses hydraulic power to raise and lower the platform. | Reduces manual labor and speeds up loading/unloading. | Integration with smart systems for automated operation. |

| Safety Features | Includes edge sensors and automatic shut-off mechanisms. | Minimizes accidents and injuries during operations. | Adoption of IoT devices for enhanced safety monitoring. |

| Durable Materials | Constructed with high-quality steel or aluminum for longevity. | Lowers replacement costs and downtime due to wear. | Development of lightweight but strong composite materials. |

| Adjustable Heights | Can be adjusted to match various trailer heights. | Increases versatility and efficiency in loading docks. | Automatic height adjustment based on trailer type. |

| Energy Efficiency | Design optimized to reduce energy consumption. | Lower operational costs and environmental impact. | Use of solar-powered or energy recovery systems. |

In modern warehousing, maximizing efficiency and safety is paramount, especially when it comes to loading and unloading cargo. Durable black hydraulic dock levelers play a crucial role in achieving these objectives. Designed to bridge the gap between trucks and loading docks, these levelers significantly enhance the operational workflow. By ensuring smooth transitions, they minimize the risks of accidents and injuries that often arise from height discrepancies, allowing workers to focus on productivity.

The operation of hydraulic dock levelers is straightforward yet effective. Utilizing a hydraulic system, the platform rises to match the truck’s height effortlessly. Once at the appropriate elevation, the lip plate extends or tilts outward, preparing for seamless cargo transfer. As the platform gradually descends onto the truck’s compartment, it creates a secure loading surface. This not only speeds up the process but also helps in maintaining the integrity of both the cargo and the equipment involved. With their robust design and efficient performance, black hydraulic dock levelers are indispensable tools in ensuring safe and effective warehouse operations.

: Dock levelers are designed to bridge the gap between loading docks and delivery vehicles, providing a smooth and safe transition for forklift trucks and goods during loading and unloading processes.

Dock levelers minimize the risk of spills and falls by accommodating different heights of trucks, leading to a safer work environment for employees and reducing potential damage to goods and vehicles.

Regular maintenance checks should include inspecting hydraulic systems for leaks, ensuring electrical components are functioning properly, verifying the efficiency of leveling mechanisms, and keeping the dock area clean to prevent obstructions.

Warehouses utilizing advanced dock levelers can reduce loading times by an average of 15-20%, leading to improved overall productivity.

A clean working environment prevents debris from obstructing the dock leveler's operation, which can lead to hazards and downtime; it has been shown to reduce accidents by up to 25% and improve productivity.

Properly maintained dock levelers can last significantly longer, potentially yielding an estimated 30% lower replacement cost over time.

The most common types of dock levelers include hydraulic, mechanical, and air-powered levelers, each utilizing different methods to adjust height and bridge gaps.

High-quality dock levelers can lead to long-term gains in efficiency and safety within the warehouse, ultimately enhancing productivity and reducing liabilities.

Training staff on proper usage helps mitigate risks associated with accidents and enhances overall productivity by ensuring that equipment is operated safely and effectively.

It is crucial to choose the right dock leveler based on load capacity and frequency of use to optimize warehouse efficiency.

A dock leveler is an essential piece of equipment in modern warehouses, designed to bridge the gap between the loading dock and the delivery vehicle. It facilitates the smooth loading and unloading of goods, which enhances overall warehouse efficiency. There are several types of dock levelers, including hydraulic, mechanical, and air-powered models, each suited to different applications and operational needs. Understanding the working mechanisms of dock levelers is crucial, as they utilize various systems to adjust their height and provide stability during movement.

The benefits of using dock levelers are significant, including reduced loading times, increased safety for workers, and minimized product damage. By improving the efficiency of warehouse operations, dock levelers play a vital role in supply chain management. Regular maintenance of dock levelers is also important to ensure their longevity and reliability. Looking ahead, trends in dock leveler technology indicate a shift towards automation and smarter systems, promising even greater efficiencies in warehouse environments.