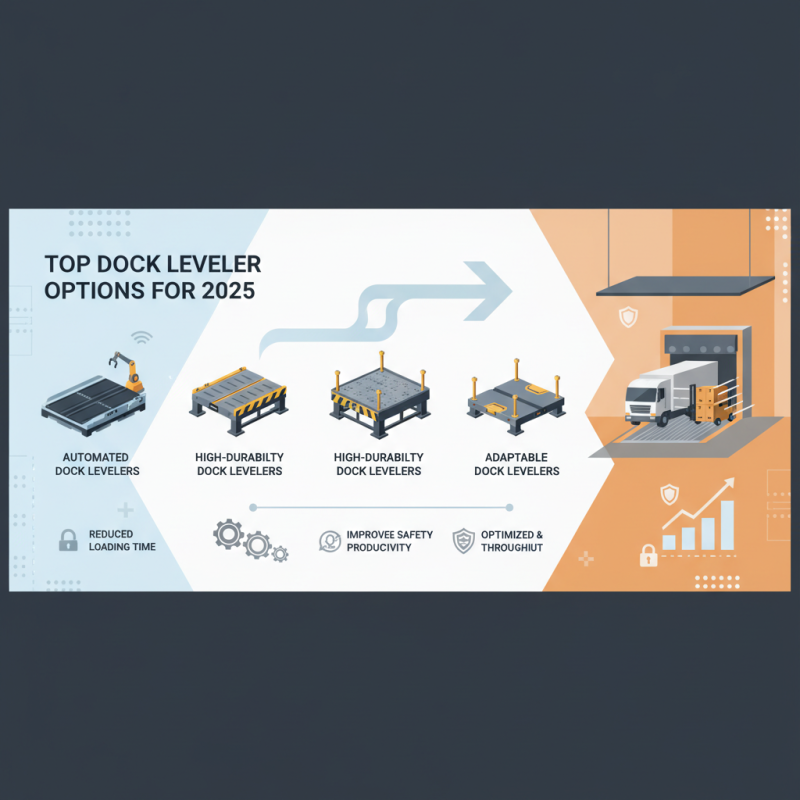

In today's fast-moving world of logistics, making your warehouse run smoothly is more important than ever. And one of the key pieces of the puzzle? Using a good Dock Leveler effectively. As John Anderson, who’s pretty much a go-to expert in dock equipment and CEO of Loading Solutions Inc., puts it, “The right Dock Leveler can seriously cut down loading and unloading times, giving a real boost to overall productivity.” Looking ahead to 2025, it’s exciting to see a lot of cool new Dock Leveler options coming out. These are tailored to different operational needs and are set to change the game in logistics.

The newest innovations aren’t just about faster workflows—they also improve safety and accessibility. Plus, they’re built to last and flexible enough to handle all kinds of freight. With automation and smart tech evolving at lightning speed, picking the right Dock Leveler is more crucial than ever for warehouse managers who want to stay competitive. As we move into this next era of logistics, understanding what these new designs bring to the table is key to making your operations as efficient and seamless as possible.

When we look at the top Dock Leveler options for 2025, it’s important to remember just how vital they are for safety, efficiency, and dependability right at the loading docks. By choosing modern Dock Leveler solutions, warehouses can speed things up, reduce delays, and create a safer, more reliable work environment. This sets everything up for future growth and success—so it’s definitely worth paying attention to these advancements.

Dock levelers play a crucial role in enhancing warehouse efficiency by providing a smooth transition between loading docks and transport vehicles. According to industry insights, nearly 26% of warehouses report inefficiencies due to improper loading dock equipment, leading to delayed operations and increased labor costs. By investing in the right dock leveler options, facilities can optimize their loading and unloading processes, reduce product damage, and improve worker safety. Modern dock levelers are designed to accommodate various vehicle heights and improve the flow of goods, which is critical in today’s fast-paced logistics environment.

Tips for selecting the best dock leveler include assessing your specific operational needs and understanding the environment in which the leveler will be used. For instance, facilities that frequently handle heavy loads may prioritize sturdier materials and features such as high-capacity ratings. Additionally, considering options that offer enhanced safety features, such as automatic edge-of-dock controls, can significantly reduce the risk of accidents and injuries during loading operations.

Furthermore, regular maintenance and inspections are vital to ensure that dock levelers function optimally. Industry reports suggest that facilities performing routine checks can increase the lifespan of their equipment by up to 50%. Implementing a proactive maintenance schedule can help prevent costly downtime and ensure that warehousing operations run smoothly and efficiently.

When selecting the best dock leveler for your facility, several key criteria should be taken into account to ensure optimal performance and efficiency. First, assess the weight capacity required for your operations. Dock levelers come in various weight ratings, and it is crucial to choose a model that can accommodate the heaviest loads you expect to handle. Consider the frequency of use as well; higher traffic may necessitate a more robust solution with increased durability.

Additionally, evaluate the types of vehicles and cargo you will be handling. Different designs, such as hydraulic, mechanical, or air-powered dock levelers, offer distinct advantages depending on your specific needs. For instance, hydraulic levelers provide seamless operation for frequent loading and unloading, while mechanical options may be suitable for less intensive use. It's also essential to consider the installation space available, including the height and width of the dock, to ensure a proper fit and safe operation.

Another important factor is the maintenance requirements associated with each type of dock leveler. Users should opt for models that offer easy access for servicing to minimize downtime and lower overall maintenance costs. Additionally, always look for features that enhance safety, such as integrated lip extensions and anti-slip surfaces, to protect your workforce during loading and unloading processes. By carefully considering these criteria, you can select a dock leveler that not only meets your operational needs but also enhances the overall efficiency of your warehouse.

This chart illustrates the efficiency ratings of various dock leveler types based on different criteria such as load capacity, operational speed, maintenance requirements, and ease of use. Higher ratings indicate better performance and suitability for warehouse operations.

When considering the top dock leveler types for enhanced efficiency in 2025, it's essential to recognize the significance of both functionality and design in optimizing warehouse operations. One of the most effective options is the Hydraulic Dock Leveler, which offers smooth, reliable performance with minimal manual intervention. These levelers can accommodate various truck heights and weights, facilitating faster loading and unloading processes. Additionally, their ability to operate seamlessly in demanding environments makes them a preferred choice for busy logistics hubs.

Another noteworthy type is the air-powered dock leveler. This innovative design utilizes compressed air to raise and lower the platform, providing a lightweight option that enhances safety and maintenance efficiency. The air-powered system reduces wear on moving parts, leading to a longer lifespan and lower operational costs. Moreover, these levelers can reduce noise levels during operation, creating a more pleasant working environment for employees.

Lastly, edge-of-dock levelers serve as a practical solution for facilities with less frequent loading needs. Their compact design enables easy installation and allows for quick adjustments to different trailer heights. By streamlining the process of moving goods in and out of a warehouse, edge-of-dock levelers contribute significantly to overall operational efficiency, making them an excellent choice for smaller warehouses aiming to maximize productivity in 2025.

As warehouses continue to evolve in efficiency and functionality, the significance of dock levelers cannot be overstated. In 2025, businesses will benefit from advanced designs that integrate innovative features, leading the way towards more streamlined operations. One prominent trend is the adoption of smart technology in dock levelers, allowing for real-time monitoring and automated adjustments to ensure optimal performance. According to the latest industry report from the Warehousing Association, warehouses that implement smart dock solutions experience a 15% increase in loading efficiency, reducing downtime and enhancing workflow.

Moreover, energy efficiency is set to play a crucial role in the selection of dock levelers in 2025. With rising operational costs and an increased focus on sustainability, modern dock levelers are designed with insulated materials that minimize energy loss during loading and unloading processes. Reports indicate that facilities utilizing energy-efficient dock solutions can cut their energy consumption by up to 20%, leading to significant cost savings over time. Additionally, features such as integrated safety systems to protect workers and equipment are becoming standard, addressing the increase in compliance regulations while ensuring a safer working environment. This progressive approach to dock leveler design reflects the industry’s commitment to enhancing productivity while prioritizing sustainability and safety.

When considering the efficiency of warehouse operations, the state of your dock levelers plays a critical role. Upgrading to more advanced dock levelers can lead to significant cost savings in the long run. While the initial investment may seem daunting, a thorough cost-benefit analysis reveals that the benefits often outweigh the expenses. Newer models typically offer improved safety features, faster loading and unloading times, and greater durability, all of which contribute to increased productivity and reduced labor costs.

Moreover, energy efficiency is another crucial aspect of modern dock levelers. Many newer systems are designed to minimize energy consumption, which can lead to lower utility bills over time. Additionally, with reduced maintenance needs and longer lifespans, upgraded dock levelers often result in fewer interruptions and repair costs. By assessing the potential return on investment, warehousing operations can make informed decisions that enhance operational efficiency while also aligning with budgetary constraints.

As warehouse operations continue to evolve, the technology surrounding dock levelers is also undergoing significant advancements. In 2025, we expect to see a shift towards smarter dock leveler systems equipped with Internet of Things (IoT) capabilities. These innovations will facilitate real-time monitoring, allowing warehouse managers to track performance metrics, identify potential maintenance needs, and improve overall operational efficiency. According to industry reports, integrating IoT technology can potentially reduce operational costs by up to 30% by minimizing downtime and optimizing workflow.

Another notable trend is the transition towards more sustainable and energy-efficient dock levelers. With increasing regulatory pressure and a growing focus on environmental responsibility, manufacturers are investing in eco-friendly materials and energy-efficient designs. Research indicates that adopting energy-efficient dock systems can lead to a reduction in energy consumption by 25% or more. This not only benefits the environment but also helps warehouses save on energy costs in the long run, making sustainability a key component of modern warehouse strategy. As these trends continue to unfold, businesses will be better positioned to enhance their efficiency and meet the demands of an ever-changing logistical landscape.

Maintaining and optimizing dock leveler performance is crucial for enhancing warehouse efficiency in 2025. Regular maintenance not only prolongs the life of the equipment but also ensures safety and minimizes downtime. According to the 2023 Warehouse Equipment Report, 20% of operational delays are attributed to equipment malfunction, underscoring the importance of addressing wear and tear early. Adaptable maintenance schedules that include daily inspections, lubrication of moving parts, and prompt repairs can significantly reduce the likelihood of unexpected failures.

Moreover, optimizing dock levelers involves assessing the loading and unloading processes to ensure they align with the equipment's specifications. For instance, ensuring that the dock levelers are suited to the weight capacities typical for your operations can prevent overloading, which is a common issue leading to costly repairs. The Industrial Docking Systems Association reported that organizations focusing on performance optimization saw a 15% increase in operational efficiency, highlighting the connection between proper handling and overall productivity. Implementing technology such as weight load indicators can further enhance understanding of dock leveler performance and facilitate informed decision-making in daily operations.

In the fast-paced world of logistics and warehousing, efficiency and safety are paramount. The durable black hydraulic dock leveler serves as an essential tool for loading dock operations, designed to bridge the gap between trucks and loading platforms seamlessly. According to industry reports, using hydraulic dock levelers can improve loading and unloading times by up to 30%, translating to significant time and cost savings for businesses.

The operation of a hydraulic dock leveler involves a sophisticated hydraulic system that elevates the platform to the desired height before engaging the lip plate. This innovative mechanism ensures a smooth transition, allowing the platform to descend gradually and stabilize against the trailer's compartment board. The safety features included in modern dock levelers, such as automatic lip extension and descent control, provide added peace of mind for dock workers, effectively reducing the risk of accidents during the loading process.

Moreover, a well-maintained hydraulic dock leveler can withstand heavy loads and environmental stressors, ensuring its durability over time. Research indicates that proper maintenance can extend the service life of these systems by up to 50%. Investing in high-quality dock levelers is not just about immediate efficiency; it is also about long-term operational safety and reduced maintenance costs, making it a smart choice for any warehouse management strategy.

: The hydraulic dock leveler is highly effective for busy logistics hubs due to its smooth performance, ability to accommodate various truck heights and weights, and its minimal manual intervention requirements.

Air-powered dock levelers utilize compressed air for operation, which reduces wear on moving parts, decreases operational costs, and minimizes noise levels, creating a safer and more pleasant working environment.

Edge-of-dock levelers are compact designs ideal for facilities with less frequent loading needs. Their easy installation and quick height adjustments make them suitable for smaller warehouses to maximize productivity.

In 2025, businesses should seek dock levelers with smart technology for real-time monitoring, energy-efficient designs to reduce consumption, and integrated safety systems to ensure compliance and worker safety.

Regular maintenance prolongs the life of dock levelers, ensures safety, and minimizes downtime. Inspections, lubrication, and prompt repairs can prevent equipment malfunction, which is a significant cause of operational delays.

Ensuring that dock levelers match typical weight capacities helps prevent overloading, reducing the likelihood of costly repairs and improving overall operational efficiency.

Implementing technology such as weight load indicators can enhance the understanding of dock leveler performance, leading to informed decision-making and improved operational efficiency.

Energy-efficient dock levelers can cut energy consumption by up to 20%, leading to significant cost savings and a reduced environmental impact during loading and unloading processes.

Addressing wear and tear early can prevent unexpected failures, which contribute to operational delays. Regular maintenance is crucial for optimal performance and long-term reliability.

Smart dock solutions allow for automated adjustments and real-time monitoring, resulting in a reported 15% increase in loading efficiency by reducing downtime and improving workflow.

In the dynamic environment of warehousing, the role of dock levelers is crucial for ensuring smooth loading and unloading processes. This article provides an overview of dock levelers, emphasizing their importance in enhancing operational efficiency. It outlines key criteria for selecting the most suitable dock levelers for a facility, highlighting various types and their specific advantages for 2025. Additionally, it discusses innovative features that can improve functionality and safety, along with a cost-benefit analysis to justify the investment in upgrading existing dock levelers.

Furthermore, the article explores future trends in dock leveler technology, offering insights into emerging developments that can influence warehouse operations. Practical tips for maintaining and optimizing dock leveler performance are also included, ensuring that facilities can maximize the effectiveness of their equipment while minimizing downtime. By understanding these elements, warehouse managers can make informed decisions to enhance productivity in their operations.